Unlock Maximum ROI with Our Lean ROI Acceleration

Unlock Maximum ROI with Our Lean ROI Acceleration

Our Lean Training for Robotics Integration

At Sikorski Robotics, we don't just sell cutting-edge robots—we empower your team to integrate them seamlessly into your operations for unparalleled efficiency. Our Lean Training program teaches proven principles like waste reduction, continuous improvement (Kaizen), and optimized process flow, tailored specifically for manufacturing teams using automation. This isn't just training; it's an ROI accelerator that transforms your robot investment into a holistic efficiency ecosystem, helping novices quickly ramp up and deliver measurable gains.

By equipping up to 10 employees with hands-on tools such as 5S organization, value stream mapping, and robot-specific waste elimination strategies, you'll see faster robot utilization, reduced downtime, and boosted productivity. Backed by industry data, our program delivers average gains like 20-30% productivity improvements and 40-50% cycle time reductions—directly enhancing your bottom line.

Why Choose Our Lean Training?

Results - Manufacturers implementing Lean principles often see benefits within 6-12 months, with ROI on Lean initiatives reaching up to 8-10x through cost savings and efficiency boosts.

Customized for Robotics - Sessions focus on integrating Lean with your robots, such as slashing setup waste by 40% and improving overall equipment effectiveness (OEE) by 15-25%.

Delivery - In-person formats, with interactive simulations, and virtual follow-up coaching.

Sample Case Study: Wiremold Company Transforms Operations with Lean Principles

Risk-Free Start - Pilot programs available for select clients to test and measure impact before full commitment.

The Wiremold Company, a manufacturer of wire conduits and electrical products, faced inefficiencies in the 1980s including long lead times, excessive inventory, poor material flow, and slow new product development (taking up to three years). After implementing Lean principles starting in 1991—focusing on Kaizen workshops, just-in-time manufacturing, value stream mapping, and empowering teams for continuous improvement—they achieved dramatic results. Productivity improved by 20% annually in the first three years, inventory levels dropped by over 75% within four years, and new product development time was reduced to less than six months. Sales quadrupled from $100 million to $400 million over eight years, with significant cost savings and enhanced profitability. By applying Lean to eliminate waste, reduce downtime, and foster a culture of ongoing optimization, Wiremold minimized errors, streamlined processes, and qualified operators more efficiently. This case highlights how our approach can yield similar transformative results for your operations.

Our Tiered Training Packages

We offer flexible pricing to fit your team size and needs, with options for groups of up to 10 employees. All packages include materials, certifications (e.g., "Grok Robotics Lean Practitioner"), and access to ROI calculators for tracking gains.

Add Lean Training to your robot purchase for up to -50% off the standalone price—making it easier to maximize your automation ROI without added budget strain.

Bundle and Save:

Quantifiable Gains You Can Expect

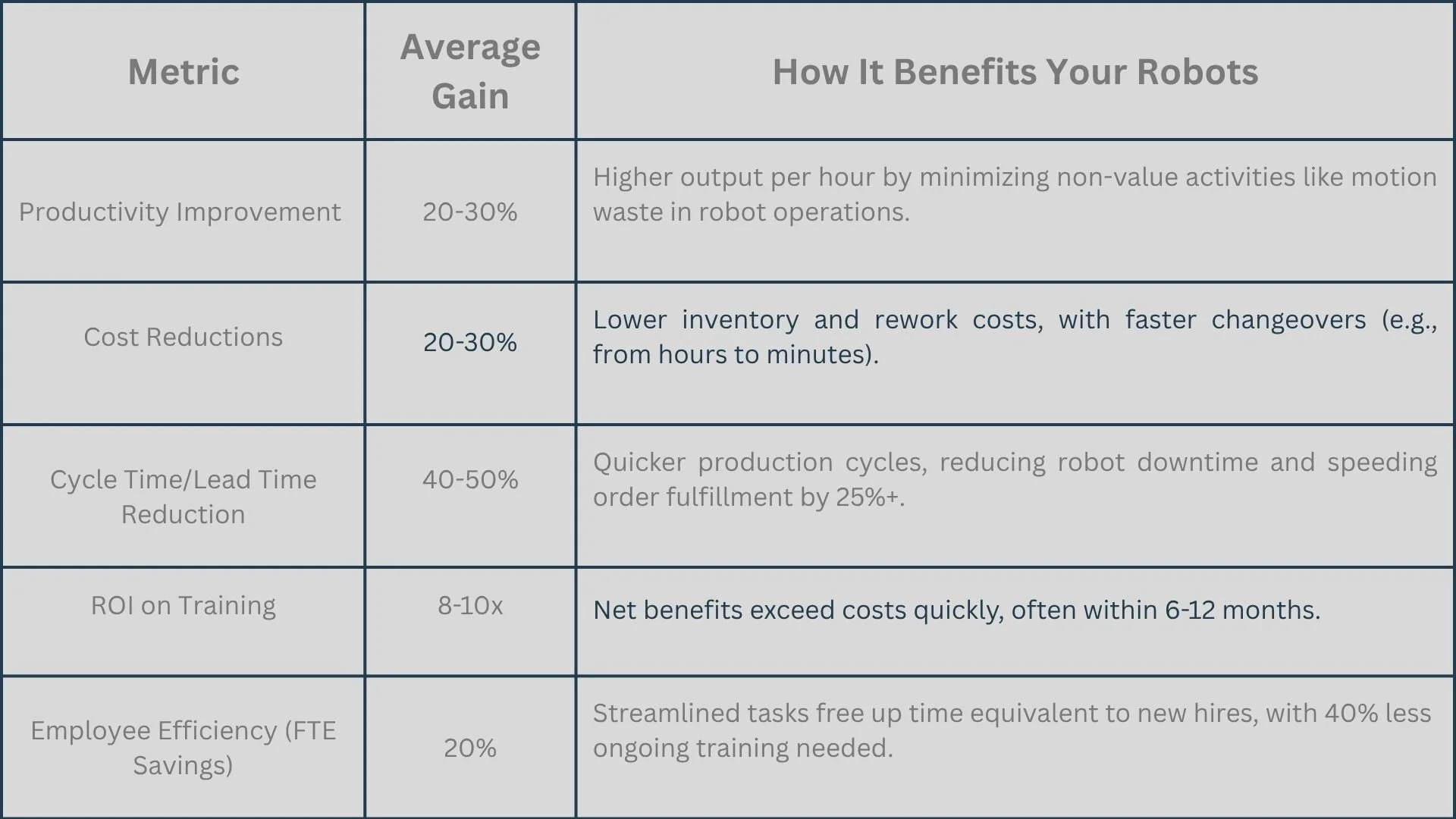

Based on studies and real-world implementations from sources like the Lean Enterprise Institute and industry reports, here's what novices achieve on average when applying Lean to robot-integrated lines:

These gains are achievable with strong attendance and application—we'll provide tools like pre/post audits and KPIs to track your progress.

Ready to supercharge your robot investment? Contact us today for a free consultation or to schedule a pilot. Let's build a leaner, more efficient future together!